USNR signs major contract with Tschopp Holzindustrie AG

At the end of 2020, USNR signed a contract with Tschopp Holzindustrie AG in Buttisholz, Switzerland, for a complete new saw line. The sawline will be a fully equipped premium production line that is custom designed to cut a maximum volume of thin boards from each log. The mill, one of Switzerland’s largest, provides the raw material for Tschopp’s production of formwork panels for the construction industry.

The log line will comprise two Logmaster HPS quad bandmills (8 bandmills in total). Designed for accurate cutting at speeds up to 180 m/min (590 ft/min), Logmaster HPS is the most advanced bandmill in USNR’s program for throughput and recovery. The line will also be equipped with USNR’s optimization and controls, and designed with flexibility and capability to accommodate complex saw patterns.

To handle the large volume of sideboards, USNR will also deliver two Catech XT edger lines that operate in the range of over 70 boards/min. These lines will be equipped with the latest optimization technology, for the highest recovery and throughput the market has to offer.

“Winning this order means that USNR can look back on 2020 as one of the best years ever in terms of sales for our European operations, despite the ongoing pandemic. This is validation of our very strong position in this region,” remarked Johan Johansson, CEO USNR AB. Johansson continues: “Located in the heart of Europe, this is a very strategic project for USNR. It will afford the wood processors in that region the opportunity to see first-hand the capabilities of USNR’s technology.”

The project is valued in the range of 13 million euro ($16 million), and all machinery will be manufactured and delivered from the USNR facility in Söderhamn, Sweden.

IT MAY INTEREST YOU

Casa Foa celebrates its 40 years with a new edition in one of the most exclusive areas of Buenos Aires

Casa Foa celebrates its 40 years with a new edition in one of the most exclusive areas of Buenos Aires

Buenos Aires, July 10, 2025. Casa Foa, the renowned exhibition of architecture, interior design, landscaping and industry that is carried out for the benefit of the Argentine Ophthalmological Foundation (FOA), announces its next edition in an exceptional scenario: the Madero Harbor district, the real estate development of mixed uses of GNV Group, located in the dike 1 of Puerto Madero. This will be the second exhibition of the year, after the successful debut of Casa Foa Academia Village in Córdoba and will take place during the months of September and October, in a space of more than 5,900 m² of exhibition, with 36 spaces intervened by architects, designers, landscapes, artists and leading companies. This edition will be a very special celebration: Casa Foa turns 40, reaffirming its role as a reference platform for innovation, creativity and Argentine design with regional projection.

Spain | In Navarra they built the longest industrialized pedestrian walkway in the world on the Arakil River

Spain | In Navarra they built the longest industrialized pedestrian walkway in the world on the Arakil River

The Navarra Foral Community celebrated a new achievement of sustainable engineering with the installation of the longest wood pedestrian walkway in the world. With a length of 86.8 meters, the structure connects the river walk between the towns of Ibero and Etxauri, on the Arakil River, without intermediate pillars and with an innovative arc structure.

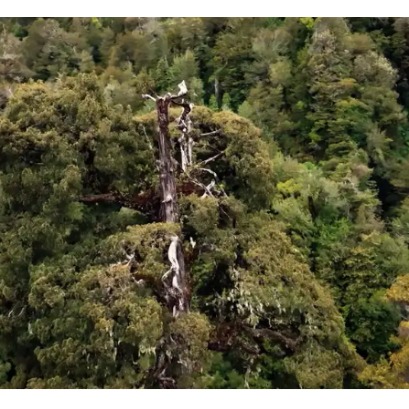

The threats that lurk to the oldest tree in the world

The threats that lurk to the oldest tree in the world

In the depths of a Chilean forest, the great grandfather stands, a tree of about 5,400 years. A highway project threatens its existence and that of the surrounding ecosystem. Empires have emerged and fallen, they have been born and fallen into oblivion languages, but this tree has resisted the passage of time: the great grandfather, around 5,400 years.