International Wood Industry Directory

Equipments, Hardware, machinery, Materials, Tooling and Woods

Use our search engine to find a company or product in the directory.

AFIPAR SH

Machines for carpentry, circular saws, nailers, staplers. Service of sharpening and repair of cutting tools.

Machines for carpentry, circular saws, nailers, staplers. Service of sharpening and repair of cutting tools.

PIERMATTEI S.A.

Since 1945, a whole career in forestry, industrialization and marketing of domestic and imported wood.

Since 1945, a whole career in forestry, industrialization and marketing of domestic and imported wood.

DECOFORMA

Decoforma specializes in the development and production of moldings and other decorative elements, construction to finish in the areas of construction and furniture. Our main strength is the recognition of an excellent price / quality ratio.

Decoforma specializes in the development and production of moldings and other decorative elements, construction to finish in the areas of construction and furniture. Our main strength is the recognition of an excellent price / quality ratio.

PRECOR SA

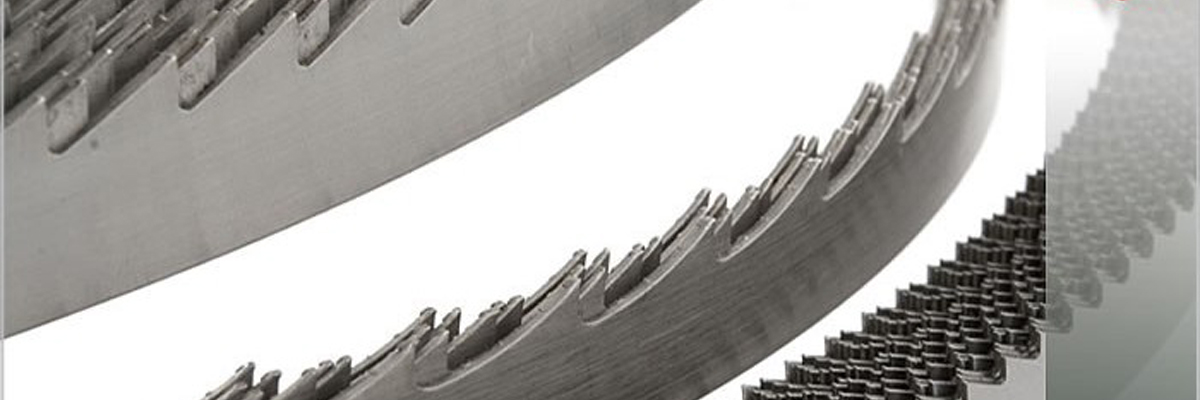

At the beginning of the last century in Italy, in a small town called Flecchia, Mr. Florindo Corte, founder and creator of our company, was born. During his youth he moved to Argentina and began working in a carpentry shop. After a few years of much sacrifice and endowed with a great vision, he undertook his own project and became a manufacturer of band saws. In 1938, he associated with Mr. Gustav Presto of Swedish origin, and together they founded PRECOR. Precor was a pioneer in using Swedish steel in Argentina for the manufacture of band saws. This decision together with an adequate production process gave Precor the prestige that it still maintains today throughout the Argentine territory. Always betting on high quality, customer service and honesty, Precor is a market leader, at the forefront of innovation and self-improvement. Today, the ISO 9001 Quality and 14001 Environmental certificates obtained confirm that our products maintain the highest standards throughout the production process. In this way we continue with the tradition of our founders, providing for more than 75 years always the best service and quality.

At the beginning of the last century in Italy, in a small town called Flecchia, Mr. Florindo Corte, founder and creator of our company, was born. During his youth he moved to Argentina and began working in a carpentry shop. After a few years of much sacrifice and endowed with a great vision, he undertook his own project and became a manufacturer of band saws. In 1938, he associated with Mr. Gustav Presto of Swedish origin, and together they founded PRECOR. Precor was a pioneer in using Swedish steel in Argentina for the manufacture of band saws. This decision together with an adequate production process gave Precor the prestige that it still maintains today throughout the Argentine territory. Always betting on high quality, customer service and honesty, Precor is a market leader, at the forefront of innovation and self-improvement. Today, the ISO 9001 Quality and 14001 Environmental certificates obtained confirm that our products maintain the highest standards throughout the production process. In this way we continue with the tradition of our founders, providing for more than 75 years always the best service and quality.

FRUND STARK SA

We are a family-owned company based in Rafaela, Province of Santa Fe, which has grown safely, effectively, and efficiently over the years. We are dedicated to the manufacture, repair, and sharpening of cutting tools for wood, aluminum, PVC, composite materials, and metals. Over more than 85 years, we have learned to face the challenges of history and the country, while continuing to strive for development. We have various production areas, including the manufacture of milling cutters, developed with automated machines that optimize processes and make them more efficient. We also specialize in circular saws, including high-speed steel saws for metal cutting. We have laser cutting equipment, and since 2018, we have offered diamond-tipped sharpening services, including maintenance and partial tool repair, as well as manufacturing in some specific cases. We represent leading global brands with a long history in the industry: FREZITE, STARK H.Q.T, KLEIN, UTENSIL CENTRO, and MEBOR. We also market through our own brand, FRUND STARK. We specialize in consulting and offering customers a specific product tailored to their needs. Therefore, we develop automated and computerized numerically controlled machines, which generates additional knowledge and provides a significant competitive advantage. Our mission is to maintain the formula that allowed us to grow and lead the P + C + R (Price + Quality + Performance) market. As a result of gradual, orderly, and strategic growth, our company has always been able to offer its customers quality solutions in a timely manner, which has become our distinguishing feature. Constant updating and the desire to pursue new products and services are the factors that have contributed to the growth of Frund Stark SA. Knowledge, development, continuous improvement... these are what define us.

We are a family-owned company based in Rafaela, Province of Santa Fe, which has grown safely, effectively, and efficiently over the years. We are dedicated to the manufacture, repair, and sharpening of cutting tools for wood, aluminum, PVC, composite materials, and metals. Over more than 85 years, we have learned to face the challenges of history and the country, while continuing to strive for development. We have various production areas, including the manufacture of milling cutters, developed with automated machines that optimize processes and make them more efficient. We also specialize in circular saws, including high-speed steel saws for metal cutting. We have laser cutting equipment, and since 2018, we have offered diamond-tipped sharpening services, including maintenance and partial tool repair, as well as manufacturing in some specific cases. We represent leading global brands with a long history in the industry: FREZITE, STARK H.Q.T, KLEIN, UTENSIL CENTRO, and MEBOR. We also market through our own brand, FRUND STARK. We specialize in consulting and offering customers a specific product tailored to their needs. Therefore, we develop automated and computerized numerically controlled machines, which generates additional knowledge and provides a significant competitive advantage. Our mission is to maintain the formula that allowed us to grow and lead the P + C + R (Price + Quality + Performance) market. As a result of gradual, orderly, and strategic growth, our company has always been able to offer its customers quality solutions in a timely manner, which has become our distinguishing feature. Constant updating and the desire to pursue new products and services are the factors that have contributed to the growth of Frund Stark SA. Knowledge, development, continuous improvement... these are what define us.

ENCHAPADORA SAN JUAN

Enchapadora San Juan S.A. is an Argentine company with more than 50 years in the market. It is dedicated to the manufacture of decorative finishes on boards with wood veneers and melamine for the furniture industry and interior design. Enchapadora San Juan S.A. it is creativity, innovation and technology. With the accumulated experience, the company supports the quality of its products and ennobles the boards through the application of surfaces, selecting high-quality raw materials to create unique, modern and innovative materials. Flexibility and adaptation to customer needs, research and attention to detail are the basic requirements to achieve excellence in the finished product. Our mission is to offer the market the latest European trends in exclusive designs and textures.

Enchapadora San Juan S.A. is an Argentine company with more than 50 years in the market. It is dedicated to the manufacture of decorative finishes on boards with wood veneers and melamine for the furniture industry and interior design. Enchapadora San Juan S.A. it is creativity, innovation and technology. With the accumulated experience, the company supports the quality of its products and ennobles the boards through the application of surfaces, selecting high-quality raw materials to create unique, modern and innovative materials. Flexibility and adaptation to customer needs, research and attention to detail are the basic requirements to achieve excellence in the finished product. Our mission is to offer the market the latest European trends in exclusive designs and textures.

RAIES MADERAS S.A.

We are a family business founded at the beginning of 1970, oriented to the lumber industry. Our main objective is to supply products that adapt to the needs of each client. We have a large stock of plates, national and imported solid wood.

We are a family business founded at the beginning of 1970, oriented to the lumber industry. Our main objective is to supply products that adapt to the needs of each client. We have a large stock of plates, national and imported solid wood.

EL EMPORIO DEL TERCIADO SA

Its activity relates to the commercialization of first brand products and specializes in the sale of agglomerated plates, agglomerated nobilized (quality melamine veneers), MDF (fiberboard), urea and phenolic ply, which allows the customer to make furniture and avant-garde designs.

Its activity relates to the commercialization of first brand products and specializes in the sale of agglomerated plates, agglomerated nobilized (quality melamine veneers), MDF (fiberboard), urea and phenolic ply, which allows the customer to make furniture and avant-garde designs.

MADERAS KIKUE

Hardwoods in general. Pine elliotis and pine parana. Special measures 11 meters. Saligna. Eucalyptus colorado. Poles beams for ceilings. Machimbres. Tarugados floors. Formwork Wood and sheet metal openings. Varnishes - lacquers.

Hardwoods in general. Pine elliotis and pine parana. Special measures 11 meters. Saligna. Eucalyptus colorado. Poles beams for ceilings. Machimbres. Tarugados floors. Formwork Wood and sheet metal openings. Varnishes - lacquers.

INGLAMIAUX

We develop ourselves in the area of Consulting and representations, applied to the Forest Industry and its value chain, sawmill, furniture and housing, as well as to projects for the use of Forest BIOMASS (Raw, Chip, Pellets, etc.). Wood and its by-products derived from the first and second transformation industry, applied to the generation of heat energy and in co-generation projects: Steam and electricity, directly or through intermediate processes such as the generation of poor gases and Diesel , which will then be used as an energy substrate in different processes or as fuels.

We develop ourselves in the area of Consulting and representations, applied to the Forest Industry and its value chain, sawmill, furniture and housing, as well as to projects for the use of Forest BIOMASS (Raw, Chip, Pellets, etc.). Wood and its by-products derived from the first and second transformation industry, applied to the generation of heat energy and in co-generation projects: Steam and electricity, directly or through intermediate processes such as the generation of poor gases and Diesel , which will then be used as an energy substrate in different processes or as fuels.

SAN VICENTE MADERAS SRL

Our company San Vicente Maderas SRL, located in the town of San Vicente, province of Misiones, dates back to 1997, when we began the production of Yerba mate and a small sawmill of native Misiones woods, which was located on the same property. , at that time it had only 8 or 10 employees. For several years we grew in both workers and clients, who demanded more infrastructure and labor to fulfill orders. To do so, we added mountain extraction equipment and at the same time we optimized the quality and preparation of the product. Currently the company is dedicated exclusively to the timber and forestry sector, both in native and implanted species, it has its own forestry and has also incorporated the production of finger laminated boards and preparation of wood for Deck and Deck tiles. It should be noted that the second generation of industrial entrepreneurs was born from the company, made up of our children who, after graduating in electromechanical engineering and a degree in hygiene and safety, formed their own company Placas Centro SRL, whose field is the production of pine and eucalyptus sheets. and native species of Misiones, with investments for a future Phenolics factory, this new generation also ventures into forestry activity, with a Parica tree nursery (laminate tree native to Brazil)

Our company San Vicente Maderas SRL, located in the town of San Vicente, province of Misiones, dates back to 1997, when we began the production of Yerba mate and a small sawmill of native Misiones woods, which was located on the same property. , at that time it had only 8 or 10 employees. For several years we grew in both workers and clients, who demanded more infrastructure and labor to fulfill orders. To do so, we added mountain extraction equipment and at the same time we optimized the quality and preparation of the product. Currently the company is dedicated exclusively to the timber and forestry sector, both in native and implanted species, it has its own forestry and has also incorporated the production of finger laminated boards and preparation of wood for Deck and Deck tiles. It should be noted that the second generation of industrial entrepreneurs was born from the company, made up of our children who, after graduating in electromechanical engineering and a degree in hygiene and safety, formed their own company Placas Centro SRL, whose field is the production of pine and eucalyptus sheets. and native species of Misiones, with investments for a future Phenolics factory, this new generation also ventures into forestry activity, with a Parica tree nursery (laminate tree native to Brazil)

COOP.DE TRABAJO HERRAMIENTAS UNION LTDA.

Cooperativa de Trabajo Herramientas Unión is a Rosario metallurgical company, manufacturing and providing services for industrial blades and cutting tools. We have more than 40 years of experience in providing solutions for the metallurgical industry. History The Herramientas Unión Work Cooperative was established in June 2000, when the former Domingo Lentini company closed its doors, leaving its workers without work. The workers were compensated with the machines and we made the decision to continue working together. So it was that we rented a new location and moved the machines to continue producing. The cooperative has grinding machines, a lathe, a universal milling machine, filing machines and a Nikon profile projector. We also have a furnace to carry out the heat treatment of the tools in our own plant. We can ensure a product with an optimal finish, because we have hardness and quality control elements. We feel indebted to our community, and for this reason we give the possibility to students from secondary schools to carry out their work practices in our cooperative.

Cooperativa de Trabajo Herramientas Unión is a Rosario metallurgical company, manufacturing and providing services for industrial blades and cutting tools. We have more than 40 years of experience in providing solutions for the metallurgical industry. History The Herramientas Unión Work Cooperative was established in June 2000, when the former Domingo Lentini company closed its doors, leaving its workers without work. The workers were compensated with the machines and we made the decision to continue working together. So it was that we rented a new location and moved the machines to continue producing. The cooperative has grinding machines, a lathe, a universal milling machine, filing machines and a Nikon profile projector. We also have a furnace to carry out the heat treatment of the tools in our own plant. We can ensure a product with an optimal finish, because we have hardness and quality control elements. We feel indebted to our community, and for this reason we give the possibility to students from secondary schools to carry out their work practices in our cooperative.

MADER-EXPO

Mader-Expo, leader in the wood frame market, whose registered trademark is Expo-trama, complying with the demands and quality standards that stand out to us. The great durability and versatility of EXPO-TRAMA make it a modern and creative option when thinking about a functional product for your home, office or business. Ideal for:• Partition panels.• Furniture fronts and openings.• Room dividers and other applications. We have a wide range of distributors throughout the country.

Mader-Expo, leader in the wood frame market, whose registered trademark is Expo-trama, complying with the demands and quality standards that stand out to us. The great durability and versatility of EXPO-TRAMA make it a modern and creative option when thinking about a functional product for your home, office or business. Ideal for:• Partition panels.• Furniture fronts and openings.• Room dividers and other applications. We have a wide range of distributors throughout the country.