International Wood Industry Directory

Equipments, Hardware, machinery, Materials, Tooling and Woods

Use our search engine to find a company or product in the directory.

ALCE HERRAJES SH

It is a family business created more than 23 years ago and has an infrastructure that provides its customers with excellent products.

It is a family business created more than 23 years ago and has an infrastructure that provides its customers with excellent products.

AFIPAR SH

Machines for carpentry, circular saws, nailers, staplers. Service of sharpening and repair of cutting tools.

Machines for carpentry, circular saws, nailers, staplers. Service of sharpening and repair of cutting tools.

MAQUINARIAS ABRAHAM

Abraham Machinery was founded by Abraham Grodnienski, born in the City of Buenos Aires, son of European immigrants. For Abraham his whole life revolved around wood, from a very young age in carpentry with his family. Where he learned the trade from his father, who was already a carpenter in Europe. In the early 70s, difficult times, with the twists and turns of life, he began to buy and sell small carpentry machines, with a lot of effort, always together with his wife Esther, he was progressing and achieved a place in the market of repaired machines with a guarantee. From 1985 his son Max began to work with him, to whom he transmitted his knowledge, and mainly his values. As well as being a father who allowed his son to carry out his own experiences so that he could learn, Abraham said: he who does nothing never makes a mistake!!! Abraham Machinery grew together with its clients, that same growth forced us in the early 90s to start importing machinery. And little by little we turned more to the importation and marketing of new machinery from different origins. Until today we have a wide range of products and representations of important international brands.

Abraham Machinery was founded by Abraham Grodnienski, born in the City of Buenos Aires, son of European immigrants. For Abraham his whole life revolved around wood, from a very young age in carpentry with his family. Where he learned the trade from his father, who was already a carpenter in Europe. In the early 70s, difficult times, with the twists and turns of life, he began to buy and sell small carpentry machines, with a lot of effort, always together with his wife Esther, he was progressing and achieved a place in the market of repaired machines with a guarantee. From 1985 his son Max began to work with him, to whom he transmitted his knowledge, and mainly his values. As well as being a father who allowed his son to carry out his own experiences so that he could learn, Abraham said: he who does nothing never makes a mistake!!! Abraham Machinery grew together with its clients, that same growth forced us in the early 90s to start importing machinery. And little by little we turned more to the importation and marketing of new machinery from different origins. Until today we have a wide range of products and representations of important international brands.

FRUND STARK SA

We are a family-owned company based in Rafaela, Province of Santa Fe, which has grown safely, effectively, and efficiently over the years. We are dedicated to the manufacture, repair, and sharpening of cutting tools for wood, aluminum, PVC, composite materials, and metals. Over more than 85 years, we have learned to face the challenges of history and the country, while continuing to strive for development. We have various production areas, including the manufacture of milling cutters, developed with automated machines that optimize processes and make them more efficient. We also specialize in circular saws, including high-speed steel saws for metal cutting. We have laser cutting equipment, and since 2018, we have offered diamond-tipped sharpening services, including maintenance and partial tool repair, as well as manufacturing in some specific cases. We represent leading global brands with a long history in the industry: FREZITE, STARK H.Q.T, KLEIN, UTENSIL CENTRO, and MEBOR. We also market through our own brand, FRUND STARK. We specialize in consulting and offering customers a specific product tailored to their needs. Therefore, we develop automated and computerized numerically controlled machines, which generates additional knowledge and provides a significant competitive advantage. Our mission is to maintain the formula that allowed us to grow and lead the P + C + R (Price + Quality + Performance) market. As a result of gradual, orderly, and strategic growth, our company has always been able to offer its customers quality solutions in a timely manner, which has become our distinguishing feature. Constant updating and the desire to pursue new products and services are the factors that have contributed to the growth of Frund Stark SA. Knowledge, development, continuous improvement... these are what define us.

We are a family-owned company based in Rafaela, Province of Santa Fe, which has grown safely, effectively, and efficiently over the years. We are dedicated to the manufacture, repair, and sharpening of cutting tools for wood, aluminum, PVC, composite materials, and metals. Over more than 85 years, we have learned to face the challenges of history and the country, while continuing to strive for development. We have various production areas, including the manufacture of milling cutters, developed with automated machines that optimize processes and make them more efficient. We also specialize in circular saws, including high-speed steel saws for metal cutting. We have laser cutting equipment, and since 2018, we have offered diamond-tipped sharpening services, including maintenance and partial tool repair, as well as manufacturing in some specific cases. We represent leading global brands with a long history in the industry: FREZITE, STARK H.Q.T, KLEIN, UTENSIL CENTRO, and MEBOR. We also market through our own brand, FRUND STARK. We specialize in consulting and offering customers a specific product tailored to their needs. Therefore, we develop automated and computerized numerically controlled machines, which generates additional knowledge and provides a significant competitive advantage. Our mission is to maintain the formula that allowed us to grow and lead the P + C + R (Price + Quality + Performance) market. As a result of gradual, orderly, and strategic growth, our company has always been able to offer its customers quality solutions in a timely manner, which has become our distinguishing feature. Constant updating and the desire to pursue new products and services are the factors that have contributed to the growth of Frund Stark SA. Knowledge, development, continuous improvement... these are what define us.

DIFRA CNC

Difra CNC is an Argentine company with more than 20 years of experience. Since 1994 we have focused on the industrial market, manufacturing CAD / CAM / CNC equipment. Our equipment is manufactured and assembled in Argentina, using the best certified quality components.

Difra CNC is an Argentine company with more than 20 years of experience. Since 1994 we have focused on the industrial market, manufacturing CAD / CAM / CNC equipment. Our equipment is manufactured and assembled in Argentina, using the best certified quality components.

LUAN - Ferroplastica Olivos S.R.L.

Luan, for more than 40 years, is a company specialized in the manufacture of wheels and accessories that supplies large furniture manufacturers and hardware houses in Argentina. Located in Lomas del Mirador (Province of Buenos Aires) Luan designs, produces, markets and distributes quality products that are needed so that the manufacturing of chairs and furniture can be carried out according to the needs and design of each client. Due to new trends in design and a high commitment to the customer, Luan expands its brand with hardware of Taiwanese origin: slides, guides, hinges, drawer sides, minifix, etc. In 2016, it bets again on movement to provide the furniture market with new product options with better quality and that are trending in Europe, thus including exclusive distribution and marketing in the country of the Austrian GRASS movement systems.»

Luan, for more than 40 years, is a company specialized in the manufacture of wheels and accessories that supplies large furniture manufacturers and hardware houses in Argentina. Located in Lomas del Mirador (Province of Buenos Aires) Luan designs, produces, markets and distributes quality products that are needed so that the manufacturing of chairs and furniture can be carried out according to the needs and design of each client. Due to new trends in design and a high commitment to the customer, Luan expands its brand with hardware of Taiwanese origin: slides, guides, hinges, drawer sides, minifix, etc. In 2016, it bets again on movement to provide the furniture market with new product options with better quality and that are trending in Europe, thus including exclusive distribution and marketing in the country of the Austrian GRASS movement systems.»

VIALRO

It was born in 1961 in the town of Valentin Alsina, Lanús District as "Vicente Laurutis e Hijos", dedicated to the manufacture of machines for the screw and bolt industry. In the 1980s, the country opened up to the entry of products from abroad, and our company imported the first threading machines to dedicate itself to the manufacture of wood screws, backed by many years of experience in the sector. Over time, the number of machinery increases, now nationally manufactured. In recent years, the trend has been to incorporate new fastening products demanded by the market. Thus, to the traditional line of Bis screws, the Dry line for wood and dry construction was incorporated.

It was born in 1961 in the town of Valentin Alsina, Lanús District as "Vicente Laurutis e Hijos", dedicated to the manufacture of machines for the screw and bolt industry. In the 1980s, the country opened up to the entry of products from abroad, and our company imported the first threading machines to dedicate itself to the manufacture of wood screws, backed by many years of experience in the sector. Over time, the number of machinery increases, now nationally manufactured. In recent years, the trend has been to incorporate new fastening products demanded by the market. Thus, to the traditional line of Bis screws, the Dry line for wood and dry construction was incorporated.

SK Global Co., Ltd

SK Global Co., Ltd. is founded in 2015. We focus on automation in the woodworking machinery field. We integrate and combine every single woodworking machine with belt conveyors, roller cases, chain conveyors with PLC and PC control. We design and develop the most comprehensive equipment and technology for the timber processing industry. Our consistent goal is to save labor, improve machine performance, provide state of the art solutions, build mutually beneficial business relationships with our clients. We provide the complete Glulam or CLT turnkey project. From our R & D sketch to final confirmed drawing with customers, manufacturing and delivering, and even installing equipment, we provide not only products but also after service by remote control and troubleshooting. No matter what situations our customers are facing, we will do our best to meet the customer’s requirements.

SK Global Co., Ltd. is founded in 2015. We focus on automation in the woodworking machinery field. We integrate and combine every single woodworking machine with belt conveyors, roller cases, chain conveyors with PLC and PC control. We design and develop the most comprehensive equipment and technology for the timber processing industry. Our consistent goal is to save labor, improve machine performance, provide state of the art solutions, build mutually beneficial business relationships with our clients. We provide the complete Glulam or CLT turnkey project. From our R & D sketch to final confirmed drawing with customers, manufacturing and delivering, and even installing equipment, we provide not only products but also after service by remote control and troubleshooting. No matter what situations our customers are facing, we will do our best to meet the customer’s requirements.

HUGO DANIEL VALETTO

Since 1979, the company Hugo Daniel Valetto, offers its customers its large and varied stock of merchandise offering a comprehensive solution for the wood, metallurgical, metalworking and automotive industries. With its headquarters in the city of Rosario (Santa Fé) with more than 1000 m2 covered, which thanks to a joint work with our branches in Buenos Aires, Córdoba and Mar del Plata. as well as exclusive sellers in Mendoza, NOA and Argentine Northwest allow us to cover a broad spectrum of our country. In addition the implementation of the ONLINE marketing system. Exclusive importers and representatives throughout the Argentine Republic, from the line of products for the Sayerlack wood industry and Dynabrade tools for the metallurgical / mechanical and automotive industries, relied on our company and all its personnel to market their products.

Since 1979, the company Hugo Daniel Valetto, offers its customers its large and varied stock of merchandise offering a comprehensive solution for the wood, metallurgical, metalworking and automotive industries. With its headquarters in the city of Rosario (Santa Fé) with more than 1000 m2 covered, which thanks to a joint work with our branches in Buenos Aires, Córdoba and Mar del Plata. as well as exclusive sellers in Mendoza, NOA and Argentine Northwest allow us to cover a broad spectrum of our country. In addition the implementation of the ONLINE marketing system. Exclusive importers and representatives throughout the Argentine Republic, from the line of products for the Sayerlack wood industry and Dynabrade tools for the metallurgical / mechanical and automotive industries, relied on our company and all its personnel to market their products.

PRECOR SA

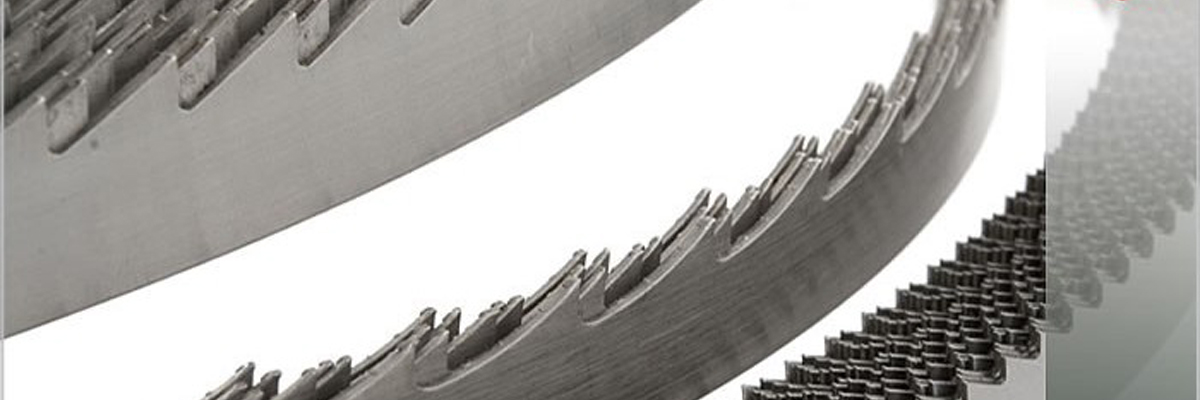

At the beginning of the last century in Italy, in a small town called Flecchia, Mr. Florindo Corte, founder and creator of our company, was born. During his youth he moved to Argentina and began working in a carpentry shop. After a few years of much sacrifice and endowed with a great vision, he undertook his own project and became a manufacturer of band saws. In 1938, he associated with Mr. Gustav Presto of Swedish origin, and together they founded PRECOR. Precor was a pioneer in using Swedish steel in Argentina for the manufacture of band saws. This decision together with an adequate production process gave Precor the prestige that it still maintains today throughout the Argentine territory. Always betting on high quality, customer service and honesty, Precor is a market leader, at the forefront of innovation and self-improvement. Today, the ISO 9001 Quality and 14001 Environmental certificates obtained confirm that our products maintain the highest standards throughout the production process. In this way we continue with the tradition of our founders, providing for more than 75 years always the best service and quality.

At the beginning of the last century in Italy, in a small town called Flecchia, Mr. Florindo Corte, founder and creator of our company, was born. During his youth he moved to Argentina and began working in a carpentry shop. After a few years of much sacrifice and endowed with a great vision, he undertook his own project and became a manufacturer of band saws. In 1938, he associated with Mr. Gustav Presto of Swedish origin, and together they founded PRECOR. Precor was a pioneer in using Swedish steel in Argentina for the manufacture of band saws. This decision together with an adequate production process gave Precor the prestige that it still maintains today throughout the Argentine territory. Always betting on high quality, customer service and honesty, Precor is a market leader, at the forefront of innovation and self-improvement. Today, the ISO 9001 Quality and 14001 Environmental certificates obtained confirm that our products maintain the highest standards throughout the production process. In this way we continue with the tradition of our founders, providing for more than 75 years always the best service and quality.

EL EMPORIO DEL TERCIADO SA

Its activity relates to the commercialization of first brand products and specializes in the sale of agglomerated plates, agglomerated nobilized (quality melamine veneers), MDF (fiberboard), urea and phenolic ply, which allows the customer to make furniture and avant-garde designs.

Its activity relates to the commercialization of first brand products and specializes in the sale of agglomerated plates, agglomerated nobilized (quality melamine veneers), MDF (fiberboard), urea and phenolic ply, which allows the customer to make furniture and avant-garde designs.

GONZALEZ TUDANCA

Gonzalez Tudanca, founded in 1978 taking as main activity the manufacture of wooden dowels (only manufacturer in South America that fulfills the DIN norms) as well as bars and accessories for curtains, cylindrical rods, corbels, and a diverse range of articles more, always guided by and towards the needs of its clients

Gonzalez Tudanca, founded in 1978 taking as main activity the manufacture of wooden dowels (only manufacturer in South America that fulfills the DIN norms) as well as bars and accessories for curtains, cylindrical rods, corbels, and a diverse range of articles more, always guided by and towards the needs of its clients

METALURGICA PESKINS SCA

Our company has an extensive history in the hardware industry for the furniture and construction industry; We design and manufacture all our products. Our marketing is carried out internally through distributors installed throughout the country and abroad through their representatives in each country. We are a company with a 20-year history in the export sector to countries such as: Puerto Rico; Mexico; USA; Dominican Republic; Paraguay.

Our company has an extensive history in the hardware industry for the furniture and construction industry; We design and manufacture all our products. Our marketing is carried out internally through distributors installed throughout the country and abroad through their representatives in each country. We are a company with a 20-year history in the export sector to countries such as: Puerto Rico; Mexico; USA; Dominican Republic; Paraguay.

AUTOPERFORANTES TEL

A 100% national company, made up of two business units; the first one oriented to the automotive industry. Its second unit is destined to the production of self-drilling screws.

A 100% national company, made up of two business units; the first one oriented to the automotive industry. Its second unit is destined to the production of self-drilling screws.

ATOR

Manufacture of wood moulding, fluted wooden pins - smooth - handles - handles - cylindrical rods - bars - all in guatambu wood - cedar - oak - etc. Products manufactured with fully automatic machinery and last generation. Prices without competition in the national market for being a true manufacturer. Check and ask for quotation of our products that will receive a response shortly. We supply our products to the main firms in the Argentine market. Shipments to the whole country - exports.

Manufacture of wood moulding, fluted wooden pins - smooth - handles - handles - cylindrical rods - bars - all in guatambu wood - cedar - oak - etc. Products manufactured with fully automatic machinery and last generation. Prices without competition in the national market for being a true manufacturer. Check and ask for quotation of our products that will receive a response shortly. We supply our products to the main firms in the Argentine market. Shipments to the whole country - exports.

PIED S.A.

Installed in an covered area of 1200 m2, and that is the main provider of bedlegs bases of our country. The first order of this unique product, what was made for the most important company mattresses manufacturer, and consisted of 8,000 units to deliver in one month. For our company meant an entire event

Installed in an covered area of 1200 m2, and that is the main provider of bedlegs bases of our country. The first order of this unique product, what was made for the most important company mattresses manufacturer, and consisted of 8,000 units to deliver in one month. For our company meant an entire event

INGLAMIAUX

We develop ourselves in the area of Consulting and representations, applied to the Forest Industry and its value chain, sawmill, furniture and housing, as well as to projects for the use of Forest BIOMASS (Raw, Chip, Pellets, etc.). Wood and its by-products derived from the first and second transformation industry, applied to the generation of heat energy and in co-generation projects: Steam and electricity, directly or through intermediate processes such as the generation of poor gases and Diesel , which will then be used as an energy substrate in different processes or as fuels.

We develop ourselves in the area of Consulting and representations, applied to the Forest Industry and its value chain, sawmill, furniture and housing, as well as to projects for the use of Forest BIOMASS (Raw, Chip, Pellets, etc.). Wood and its by-products derived from the first and second transformation industry, applied to the generation of heat energy and in co-generation projects: Steam and electricity, directly or through intermediate processes such as the generation of poor gases and Diesel , which will then be used as an energy substrate in different processes or as fuels.

BIASSONI E HIJOS SAICA

At Biassoni we currently design and manufacture more than 1,300 hand tools for the construction, agricultural, fruit and vegetable and mechanical industries. We have a team of 130 people distributed in 3 industrial plants, with a total covered area of 7,800 m². Our 75 years of uninterrupted work positions us as a benchmark for the national industry, permanently betting on innovation with a strong commitment to quality, and with a strong presence throughout the country and in South America.

At Biassoni we currently design and manufacture more than 1,300 hand tools for the construction, agricultural, fruit and vegetable and mechanical industries. We have a team of 130 people distributed in 3 industrial plants, with a total covered area of 7,800 m². Our 75 years of uninterrupted work positions us as a benchmark for the national industry, permanently betting on innovation with a strong commitment to quality, and with a strong presence throughout the country and in South America.

PERFILES DEL SOL

With more than ten years of experience in the field of aluminum, our company proposes an optimal and exclusive quality in terms of design and finish of the products we offer. Focusing on the area of kitchen furniture, closets and derivatives, we propose a wide variety of solutions for the needs of our customers, who have been with us since our beginnings, and who, with their trust, allow us to continue growing day by day.

With more than ten years of experience in the field of aluminum, our company proposes an optimal and exclusive quality in terms of design and finish of the products we offer. Focusing on the area of kitchen furniture, closets and derivatives, we propose a wide variety of solutions for the needs of our customers, who have been with us since our beginnings, and who, with their trust, allow us to continue growing day by day.

CLARKE S INDUSTRIES Inc.

Since 1952 Clarke’s primary business is the supply of Pneumatic Dust Collection and Transport Systems as well as Bulk Material Handling and Storage equipment. To compliment the Pneumatic Systems, Clarke’s manufactures a complete line of Safety Equipment including Spark Detection and Extinguishment Systems, our PyroGuard line of equipment. No Job is too Big or Small! Trust the experts! What ever your need is, we can help.

Since 1952 Clarke’s primary business is the supply of Pneumatic Dust Collection and Transport Systems as well as Bulk Material Handling and Storage equipment. To compliment the Pneumatic Systems, Clarke’s manufactures a complete line of Safety Equipment including Spark Detection and Extinguishment Systems, our PyroGuard line of equipment. No Job is too Big or Small! Trust the experts! What ever your need is, we can help.

LYH PLACAS

We are distributors of: melamine, phenolic, mdf, osb, fittings, wardrobe kit, floating and wooden floors.

Fittings - Singing - Glues - Screws - Personalized and perfect cuts!!

Everything for the carpenter and what you need to renovate your house!!

We are distributors of: melamine, phenolic, mdf, osb, fittings, wardrobe kit, floating and wooden floors.

Fittings - Singing - Glues - Screws - Personalized and perfect cuts!!

Everything for the carpenter and what you need to renovate your house!!

HERRAJES NORTE

Herrajes NORTE SRL puts at your disposal the experience accumulated since 1980, as a company specialized in hardware and accessories for furniture and the comfort of your home, providing technical advice, service, quality and efficiency.- Past and present The company was founded in 1980. The main activity revolved around the furniture industry, supplying them with the necessary accessories and tools.- In 1986 we acquired a plastic injection molding machine, in this way we began to produce plastic hardware and accessories. Then we began to supply other businesses in the sector, opening ourselves as wholesalers and retailers. At the end of 1996, a new injection plant was incorporated with the objective of improving the quality of the products that were produced until now and satisfying the growing demand. In 1998 it opened its new location with the purpose of providing a better quality of service to the public.- Since 2000, different international companies dedicated to the production and marketing of machinery and supplies for the furniture industry trusted Herrajes NORTE SRL, making us their representatives throughout the territory of the Argentine Republic.- Currently Herrajes NORTE SRL represents the most recognized houses in the sector at a national and international level.-

Herrajes NORTE SRL puts at your disposal the experience accumulated since 1980, as a company specialized in hardware and accessories for furniture and the comfort of your home, providing technical advice, service, quality and efficiency.- Past and present The company was founded in 1980. The main activity revolved around the furniture industry, supplying them with the necessary accessories and tools.- In 1986 we acquired a plastic injection molding machine, in this way we began to produce plastic hardware and accessories. Then we began to supply other businesses in the sector, opening ourselves as wholesalers and retailers. At the end of 1996, a new injection plant was incorporated with the objective of improving the quality of the products that were produced until now and satisfying the growing demand. In 1998 it opened its new location with the purpose of providing a better quality of service to the public.- Since 2000, different international companies dedicated to the production and marketing of machinery and supplies for the furniture industry trusted Herrajes NORTE SRL, making us their representatives throughout the territory of the Argentine Republic.- Currently Herrajes NORTE SRL represents the most recognized houses in the sector at a national and international level.-

TEPELCO S.A.

In 1969, TEPELCO SACI began its activities, dedicated to the design and manufacture of equipment for industrial ventilation systems, localized aspiration and pneumatic transportation of materials. At the beginning of the 70s and with the obtaining of the Anderson IBEC and Torit Corp. licenses from the USA. In the U.S., more products were incorporated, such as dust collectors, for the treatment of gaseous effluents, making TEPELCO the first company in Argentina to introduce and manufacture cartridge filter equipment, thereby achieving better efficiency in particle retention. In the mid-90s, the licenses were finalized and with the experience acquired, equipment with its own technology was developed, for example gas scrubbers (wet separation equipment). In recent years, the best technology in filter fabrics and cartridges for air filtration has been incorporated, through the representation of the firm TDC Filter Manufacturing Inc. Also incorporating training and permanent education in the area. Since its creation, TEPELCO has provided services and provision of equipment to the main industries in Argentina in different areas such as pharmaceutical and veterinary laboratories, mining, construction, chemistry, road, food, cement, metalworking, automotive, wood, steel, etc. also having equipment installed in Chile, Uruguay, Paraguay, Brazil, Colombia, Venezuela, Russia and Malaysia. With 45 years of experience, TEPELCO built a reputation that positions it as a leading company in its specialty.

In 1969, TEPELCO SACI began its activities, dedicated to the design and manufacture of equipment for industrial ventilation systems, localized aspiration and pneumatic transportation of materials. At the beginning of the 70s and with the obtaining of the Anderson IBEC and Torit Corp. licenses from the USA. In the U.S., more products were incorporated, such as dust collectors, for the treatment of gaseous effluents, making TEPELCO the first company in Argentina to introduce and manufacture cartridge filter equipment, thereby achieving better efficiency in particle retention. In the mid-90s, the licenses were finalized and with the experience acquired, equipment with its own technology was developed, for example gas scrubbers (wet separation equipment). In recent years, the best technology in filter fabrics and cartridges for air filtration has been incorporated, through the representation of the firm TDC Filter Manufacturing Inc. Also incorporating training and permanent education in the area. Since its creation, TEPELCO has provided services and provision of equipment to the main industries in Argentina in different areas such as pharmaceutical and veterinary laboratories, mining, construction, chemistry, road, food, cement, metalworking, automotive, wood, steel, etc. also having equipment installed in Chile, Uruguay, Paraguay, Brazil, Colombia, Venezuela, Russia and Malaysia. With 45 years of experience, TEPELCO built a reputation that positions it as a leading company in its specialty.

COOP.DE TRABAJO HERRAMIENTAS UNION LTDA.

Cooperativa de Trabajo Herramientas Unión is a Rosario metallurgical company, manufacturing and providing services for industrial blades and cutting tools. We have more than 40 years of experience in providing solutions for the metallurgical industry. History The Herramientas Unión Work Cooperative was established in June 2000, when the former Domingo Lentini company closed its doors, leaving its workers without work. The workers were compensated with the machines and we made the decision to continue working together. So it was that we rented a new location and moved the machines to continue producing. The cooperative has grinding machines, a lathe, a universal milling machine, filing machines and a Nikon profile projector. We also have a furnace to carry out the heat treatment of the tools in our own plant. We can ensure a product with an optimal finish, because we have hardness and quality control elements. We feel indebted to our community, and for this reason we give the possibility to students from secondary schools to carry out their work practices in our cooperative.

Cooperativa de Trabajo Herramientas Unión is a Rosario metallurgical company, manufacturing and providing services for industrial blades and cutting tools. We have more than 40 years of experience in providing solutions for the metallurgical industry. History The Herramientas Unión Work Cooperative was established in June 2000, when the former Domingo Lentini company closed its doors, leaving its workers without work. The workers were compensated with the machines and we made the decision to continue working together. So it was that we rented a new location and moved the machines to continue producing. The cooperative has grinding machines, a lathe, a universal milling machine, filing machines and a Nikon profile projector. We also have a furnace to carry out the heat treatment of the tools in our own plant. We can ensure a product with an optimal finish, because we have hardness and quality control elements. We feel indebted to our community, and for this reason we give the possibility to students from secondary schools to carry out their work practices in our cooperative.

CASERMEIRO S.R.L.

We started commercial activities in 1980, where it was originally linked to the commercialization of machines, pneumatic tools and supplies for the industry. Over time, we incorporated different products related to the activity, such as the wholesale distribution of self-drilling screws of various brands. We currently have a new industrial plant of 3000 m2 covered manufacturing a wide range of screws, supplying the national industry, among which we can mention the wood industry, the white line industry, the construction industry, and industrial metalworking in general.

We started commercial activities in 1980, where it was originally linked to the commercialization of machines, pneumatic tools and supplies for the industry. Over time, we incorporated different products related to the activity, such as the wholesale distribution of self-drilling screws of various brands. We currently have a new industrial plant of 3000 m2 covered manufacturing a wide range of screws, supplying the national industry, among which we can mention the wood industry, the white line industry, the construction industry, and industrial metalworking in general.