International Wood Industry Directory

Equipments, Hardware, machinery, Materials, Tooling and Woods

Use our search engine to find a company or product in the directory.

JACKSON LUMBER HARVESTER CO., Inc.

AUXILIARY EQUIPMENTS

Scouring shaving machines to the vanguard in wood shaving

AUXILIARY EQUIPMENTS

Scouring shaving machines to the vanguard in wood shaving

INGLAMIAUX

AUXILIARY EQUIPMENTS

We develop ourselves in the area of Consulting and representations, applied to the Forest Industry and its value chain, sawmill, furniture and housing, as well as to projects for the use of Forest BIOMASS (Raw, Chip, Pellets, etc.). Wood and its by-products derived from the first and second transformation industry, applied to the generation of heat energy and in co-generation projects: Steam and electricity, directly or through intermediate processes such as the generation of poor gases and Diesel , which will then be used as an energy substrate in different processes or as fuels.

AUXILIARY EQUIPMENTS

We develop ourselves in the area of Consulting and representations, applied to the Forest Industry and its value chain, sawmill, furniture and housing, as well as to projects for the use of Forest BIOMASS (Raw, Chip, Pellets, etc.). Wood and its by-products derived from the first and second transformation industry, applied to the generation of heat energy and in co-generation projects: Steam and electricity, directly or through intermediate processes such as the generation of poor gases and Diesel , which will then be used as an energy substrate in different processes or as fuels.

MAQUINARIAS ABRAHAM

AUXILIARY EQUIPMENTS

Abraham Machinery was founded by Abraham Grodnienski, born in the City of Buenos Aires, son of European immigrants. For Abraham his whole life revolved around wood, from a very young age in carpentry with his family. Where he learned the trade from his father, who was already a carpenter in Europe. In the early 70s, difficult times, with the twists and turns of life, he began to buy and sell small carpentry machines, with a lot of effort, always together with his wife Esther, he was progressing and achieved a place in the market of repaired machines with a guarantee. From 1985 his son Max began to work with him, to whom he transmitted his knowledge, and mainly his values. As well as being a father who allowed his son to carry out his own experiences so that he could learn, Abraham said: he who does nothing never makes a mistake!!! Abraham Machinery grew together with its clients, that same growth forced us in the early 90s to start importing machinery. And little by little we turned more to the importation and marketing of new machinery from different origins. Until today we have a wide range of products and representations of important international brands.

AUXILIARY EQUIPMENTS

Abraham Machinery was founded by Abraham Grodnienski, born in the City of Buenos Aires, son of European immigrants. For Abraham his whole life revolved around wood, from a very young age in carpentry with his family. Where he learned the trade from his father, who was already a carpenter in Europe. In the early 70s, difficult times, with the twists and turns of life, he began to buy and sell small carpentry machines, with a lot of effort, always together with his wife Esther, he was progressing and achieved a place in the market of repaired machines with a guarantee. From 1985 his son Max began to work with him, to whom he transmitted his knowledge, and mainly his values. As well as being a father who allowed his son to carry out his own experiences so that he could learn, Abraham said: he who does nothing never makes a mistake!!! Abraham Machinery grew together with its clients, that same growth forced us in the early 90s to start importing machinery. And little by little we turned more to the importation and marketing of new machinery from different origins. Until today we have a wide range of products and representations of important international brands.

AFIPAR SH

AUXILIARY EQUIPMENTS

Machines for carpentry, circular saws, nailers, staplers. Service of sharpening and repair of cutting tools.

AUXILIARY EQUIPMENTS

Machines for carpentry, circular saws, nailers, staplers. Service of sharpening and repair of cutting tools.

CONTROL LOGIC

AUXILIARY EQUIPMENTS

THERMAL, FLAME AND INFRARED SPARK DETECTORS FOR INDUSTRIAL ENVIRONMENTS. THE FASTEST AND EFFECTIVE FIRE DETECTION SYSTEMS

AUXILIARY EQUIPMENTS

THERMAL, FLAME AND INFRARED SPARK DETECTORS FOR INDUSTRIAL ENVIRONMENTS. THE FASTEST AND EFFECTIVE FIRE DETECTION SYSTEMS

COMBILIFT

AUXILIARY EQUIPMENTS

We are the subsidiary of Combilift Ltd. that serves the Spanish-speaking markets, including Portugal, from our headquarters in the Iberian Peninsula and Panama. Attending the different regions of South America, Central America, Mexico, Portugal and Spain.

AUXILIARY EQUIPMENTS

We are the subsidiary of Combilift Ltd. that serves the Spanish-speaking markets, including Portugal, from our headquarters in the Iberian Peninsula and Panama. Attending the different regions of South America, Central America, Mexico, Portugal and Spain.

SK Global Co., Ltd

AUXILIARY EQUIPMENTS

SK Global Co., Ltd. is founded in 2015. We focus on automation in the woodworking machinery field. We integrate and combine every single woodworking machine with belt conveyors, roller cases, chain conveyors with PLC and PC control. We design and develop the most comprehensive equipment and technology for the timber processing industry. Our consistent goal is to save labor, improve machine performance, provide state of the art solutions, build mutually beneficial business relationships with our clients. We provide the complete Glulam or CLT turnkey project. From our R & D sketch to final confirmed drawing with customers, manufacturing and delivering, and even installing equipment, we provide not only products but also after service by remote control and troubleshooting. No matter what situations our customers are facing, we will do our best to meet the customer’s requirements.

AUXILIARY EQUIPMENTS

SK Global Co., Ltd. is founded in 2015. We focus on automation in the woodworking machinery field. We integrate and combine every single woodworking machine with belt conveyors, roller cases, chain conveyors with PLC and PC control. We design and develop the most comprehensive equipment and technology for the timber processing industry. Our consistent goal is to save labor, improve machine performance, provide state of the art solutions, build mutually beneficial business relationships with our clients. We provide the complete Glulam or CLT turnkey project. From our R & D sketch to final confirmed drawing with customers, manufacturing and delivering, and even installing equipment, we provide not only products but also after service by remote control and troubleshooting. No matter what situations our customers are facing, we will do our best to meet the customer’s requirements.

USNR

AUXILIARY EQUIPMENTS - SuperSaver line saves space and maximizes your investment

AUXILIARY EQUIPMENTS - SuperSaver line saves space and maximizes your investment

CLARKE S INDUSTRIES Inc.

AUXILIARY EQUIPMENTS

Since 1952 Clarke’s primary business is the supply of Pneumatic Dust Collection and Transport Systems as well as Bulk Material Handling and Storage equipment. To compliment the Pneumatic Systems, Clarke’s manufactures a complete line of Safety Equipment including Spark Detection and Extinguishment Systems, our PyroGuard line of equipment. No Job is too Big or Small! Trust the experts! What ever your need is, we can help.

AUXILIARY EQUIPMENTS

Since 1952 Clarke’s primary business is the supply of Pneumatic Dust Collection and Transport Systems as well as Bulk Material Handling and Storage equipment. To compliment the Pneumatic Systems, Clarke’s manufactures a complete line of Safety Equipment including Spark Detection and Extinguishment Systems, our PyroGuard line of equipment. No Job is too Big or Small! Trust the experts! What ever your need is, we can help.

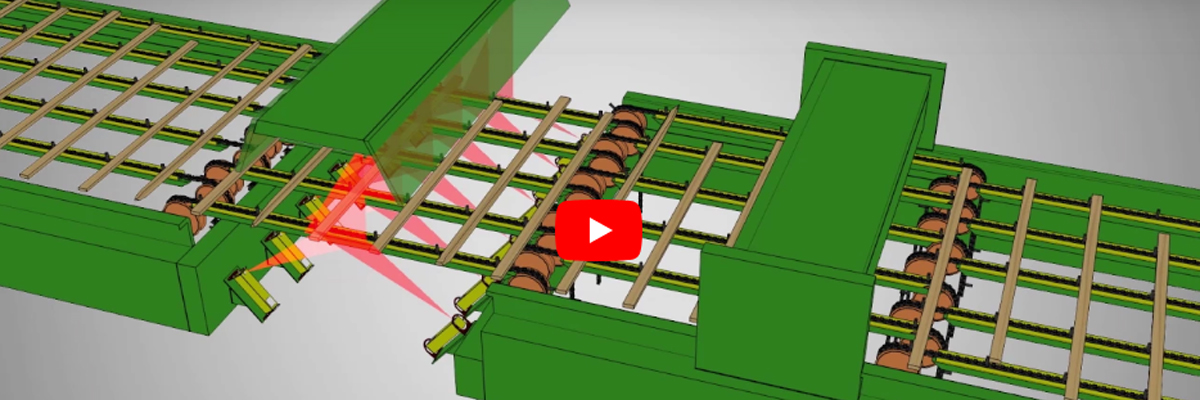

JOESCAN

AUXILIARY EQUIPMENTS

JOESCAN Delivers: Speed. Accuracy. Reliability 3-D laser scanning has revolutionized the wood products industry. Scanning and profiling logs and boards with non-contact laser measurement is a major breakthrough, allowing mills to optimize their cutting decisions and maximize yield. But the first generation of machine vision was complex, unreliable and expensive. In the great American tradition, someone decided there had to be a better way – and then built it. That’s how JoeScan started, and that same principle drives us to continue improving laser scanning.

The JoeScan Advantage JoeScan scanners offer the best of ingenuity and technology. Every JoeScan JS-25 scan head is simple to install, easy to use, built tough for maximum reliability, and priced to make scanning affordable for your application. And JoeScan products are backed by helpful people, online support and the industrys only 5-year warranty. The JoeScan advantage is easy to sum up: Our scan heads are faster, more accurate and more reliable than other products out there

AUXILIARY EQUIPMENTS

JOESCAN Delivers: Speed. Accuracy. Reliability 3-D laser scanning has revolutionized the wood products industry. Scanning and profiling logs and boards with non-contact laser measurement is a major breakthrough, allowing mills to optimize their cutting decisions and maximize yield. But the first generation of machine vision was complex, unreliable and expensive. In the great American tradition, someone decided there had to be a better way – and then built it. That’s how JoeScan started, and that same principle drives us to continue improving laser scanning.

The JoeScan Advantage JoeScan scanners offer the best of ingenuity and technology. Every JoeScan JS-25 scan head is simple to install, easy to use, built tough for maximum reliability, and priced to make scanning affordable for your application. And JoeScan products are backed by helpful people, online support and the industrys only 5-year warranty. The JoeScan advantage is easy to sum up: Our scan heads are faster, more accurate and more reliable than other products out there

TEPELCO S.A.

AUXILIARY EQUIPMENTS

In 1969, TEPELCO SACI began its activities, dedicated to the design and manufacture of equipment for industrial ventilation systems, localized aspiration and pneumatic transportation of materials. At the beginning of the 70s and with the obtaining of the Anderson IBEC and Torit Corp. licenses from the USA. In the U.S., more products were incorporated, such as dust collectors, for the treatment of gaseous effluents, making TEPELCO the first company in Argentina to introduce and manufacture cartridge filter equipment, thereby achieving better efficiency in particle retention. In the mid-90s, the licenses were finalized and with the experience acquired, equipment with its own technology was developed, for example gas scrubbers (wet separation equipment). In recent years, the best technology in filter fabrics and cartridges for air filtration has been incorporated, through the representation of the firm TDC Filter Manufacturing Inc. Also incorporating training and permanent education in the area. Since its creation, TEPELCO has provided services and provision of equipment to the main industries in Argentina in different areas such as pharmaceutical and veterinary laboratories, mining, construction, chemistry, road, food, cement, metalworking, automotive, wood, steel, etc. also having equipment installed in Chile, Uruguay, Paraguay, Brazil, Colombia, Venezuela, Russia and Malaysia. With 45 years of experience, TEPELCO built a reputation that positions it as a leading company in its specialty.

AUXILIARY EQUIPMENTS

In 1969, TEPELCO SACI began its activities, dedicated to the design and manufacture of equipment for industrial ventilation systems, localized aspiration and pneumatic transportation of materials. At the beginning of the 70s and with the obtaining of the Anderson IBEC and Torit Corp. licenses from the USA. In the U.S., more products were incorporated, such as dust collectors, for the treatment of gaseous effluents, making TEPELCO the first company in Argentina to introduce and manufacture cartridge filter equipment, thereby achieving better efficiency in particle retention. In the mid-90s, the licenses were finalized and with the experience acquired, equipment with its own technology was developed, for example gas scrubbers (wet separation equipment). In recent years, the best technology in filter fabrics and cartridges for air filtration has been incorporated, through the representation of the firm TDC Filter Manufacturing Inc. Also incorporating training and permanent education in the area. Since its creation, TEPELCO has provided services and provision of equipment to the main industries in Argentina in different areas such as pharmaceutical and veterinary laboratories, mining, construction, chemistry, road, food, cement, metalworking, automotive, wood, steel, etc. also having equipment installed in Chile, Uruguay, Paraguay, Brazil, Colombia, Venezuela, Russia and Malaysia. With 45 years of experience, TEPELCO built a reputation that positions it as a leading company in its specialty.

COOP.DE TRABAJO HERRAMIENTAS UNION LTDA.

AUXILIARY EQUIPMENTS

Cooperativa de Trabajo Herramientas Unión is a Rosario metallurgical company, manufacturing and providing services for industrial blades and cutting tools. We have more than 40 years of experience in providing solutions for the metallurgical industry. History The Herramientas Unión Work Cooperative was established in June 2000, when the former Domingo Lentini company closed its doors, leaving its workers without work. The workers were compensated with the machines and we made the decision to continue working together. So it was that we rented a new location and moved the machines to continue producing. The cooperative has grinding machines, a lathe, a universal milling machine, filing machines and a Nikon profile projector. We also have a furnace to carry out the heat treatment of the tools in our own plant. We can ensure a product with an optimal finish, because we have hardness and quality control elements. We feel indebted to our community, and for this reason we give the possibility to students from secondary schools to carry out their work practices in our cooperative.

AUXILIARY EQUIPMENTS

Cooperativa de Trabajo Herramientas Unión is a Rosario metallurgical company, manufacturing and providing services for industrial blades and cutting tools. We have more than 40 years of experience in providing solutions for the metallurgical industry. History The Herramientas Unión Work Cooperative was established in June 2000, when the former Domingo Lentini company closed its doors, leaving its workers without work. The workers were compensated with the machines and we made the decision to continue working together. So it was that we rented a new location and moved the machines to continue producing. The cooperative has grinding machines, a lathe, a universal milling machine, filing machines and a Nikon profile projector. We also have a furnace to carry out the heat treatment of the tools in our own plant. We can ensure a product with an optimal finish, because we have hardness and quality control elements. We feel indebted to our community, and for this reason we give the possibility to students from secondary schools to carry out their work practices in our cooperative.

CASERMEIRO S.R.L.

AUXILIARY EQUIPMENTS

We started commercial activities in 1980, where it was originally linked to the commercialization of machines, pneumatic tools and supplies for the industry. Over time, we incorporated different products related to the activity, such as the wholesale distribution of self-drilling screws of various brands. We currently have a new industrial plant of 3000 m2 covered manufacturing a wide range of screws, supplying the national industry, among which we can mention the wood industry, the white line industry, the construction industry, and industrial metalworking in general.

AUXILIARY EQUIPMENTS

We started commercial activities in 1980, where it was originally linked to the commercialization of machines, pneumatic tools and supplies for the industry. Over time, we incorporated different products related to the activity, such as the wholesale distribution of self-drilling screws of various brands. We currently have a new industrial plant of 3000 m2 covered manufacturing a wide range of screws, supplying the national industry, among which we can mention the wood industry, the white line industry, the construction industry, and industrial metalworking in general.