WEMHÖNER Surface Technologies

Machinery and equipment for value added panel processing. Design, construction and commissioning of production lines. Wemhöner produce machines and systems for upgrading of wood based panels and other materials. The product portfolio ranges from short-cycle press systems to 3D membrane and vacuum press lines. It includes digital and direct printing systems, lacquering lines, lightweight panel systems, throughfeed press lines, custom-made equipment and special press lines. Wemhöner is the world market leader for short-cycle press lines and 3D Variopress® technology. Wemhöner place great emphasis on jointly formulating innovative processes. The Wemhöner innovations are distinguished by the numerous patents they carry.

Products

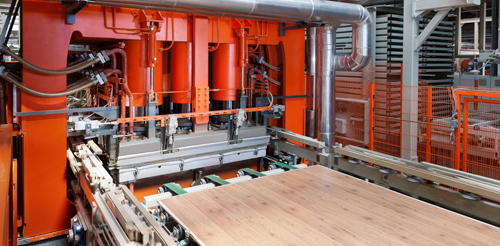

- Highest level of expertise in direct lamination. Wemhöner short-cycle press lines for melamine direct lamination have played an essential role in the worldwide furniture and laminate flooring industry for over 40 years. We set technological standards with EIR synchronous pore technology in both single and double sided applications. Speed, reliability and efficiency of Wemhöner short-cycle press plants are the basis for the Herford Company’s technological and global market leadership.

- Our vision of finishing in the third dimension Wemhöner 3D Variopress® lines: conceived in dialogue with our customers. Manufactured in accordance with highest German quality standards. Installed at our customers’ sites around the world. Day after day, more than 800 Variopress® lines laminate three-dimensional components with thermoplastic foils, veneers and other deformable materials. They enable the production of furniture fronts with glossy surfaces, deeply textured designs and curved fronts. Many of these vacuum press lines incorporate the patented VarioPin® system and our multifunction frame. Wemhöner 3D Variopress® lines stand for the realization of our vision of finishing in the third dimension.

- Basic 1000 and Basic Plus Entry-level access to Wemhöner 3D pressing technology: The Variopress® Basic 1000 systems are the entry systems into Wemhöner 3D-press technology. The high flexibility of the individual units is ideal for small series, pilot series and individual pieces such as for shop fitting, boat or custom furniture. The Basic 1000 may be expanded at anytime. There is a choice between a one or two tray in feed system. In addition the Basic 1000 can be upgraded at any time to Basic Plus. The capacity of the press line is increased significantly by adding the VarioPin® system and a turning device. A special feature in this series is the Wemhöner VarioSize system - a joint development with our customers. The infeed tray is variably used depending on the design. The advantages for the operator: A reduction of the foil waste. A third tray is added for the production of curved fronts.

- Universal 2000 The Variopress® Universal 2000 is our development for applications in the medium capacity range. It offers excellent flexibility in the production of high-gloss surfaces, curved fronts and 3D veneer applications. Various different automation options are available for feeding MDF pieces and foil. The feed to our cross-press is very versatile. To facilitate loading and unloading five trays circulate within the feed. In addition to the now standard pin and turning systems the Universal 2000 is also provided with 8 bar chamber pressure for high gloss applications.

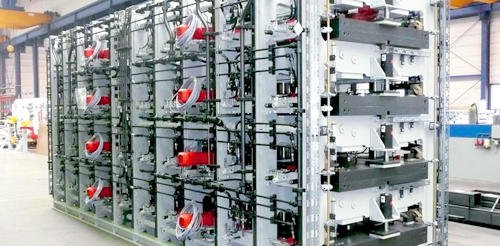

- Professional 3000 At Wemhöner the Variopress® Professional 3000 is considered a custom made, high-performance system. In the press lines all technical accessories are integrated: automatic MDF feeding onto the tray, the VarioPin® system and the feed tray with vertical tray circulation on two levels with up to eight loading trays. A film sheet feeding via a paternoster is already included to support high-performance systems with customer-specific warehouse management. A horizontal paternoster with up to 70 storage spaces and fully automatic foil change are in use. An automatic turning system that can be connected to the cutting and brushing machines is also included.

- Precisely tailored to the customer. Wemhöner single and multi daylight throughfeed presses are fully integrated solutions. They are designed and constructed to fulfil the precise requirements of each customer’s specific production processes. Loading, laying and stacking systems that satisfy the most demanding needs are developed in close collaboration with our customers.

- Single daylight throughfeed press lines The single daylight design of the Wemhöner throughfeed press lines is ideal for the finishing of wood materials with veneers. From entry-level models to fully automated production lines: You have a flexible choice of serial production models or customised solutions developed especially to meet your specific needs. We offer a broad spectrum of equipment options: Individual control of pressure cylinders Specific press pressure using an automatic batch measuring system Simultaneous lamination of two different surface materials Fast changeover between urea and PVAc adhesives Automatic feeding of veneers, finished foils, laminates and counteracting paper The precise transport of the workpiece within the press daylight is ensured using linearly regulated foil belts. Cylinders arranged above the pressure plates provide a uniform pressure distribution of up to 200 N/cm². Fluid media such as thermal oil or hot water heat the heating plates to 130°C.

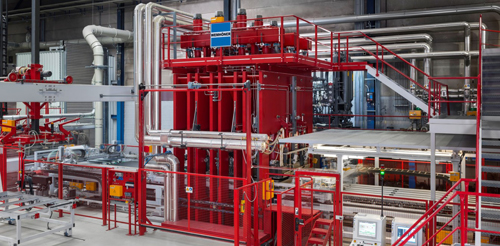

- Multi daylight throughfeed press lines Multi daylight throughfeed press line concepts from Wemhöner are perfectly matched to the product, production process, capacity and the local conditions of the customer. The systems are designed and manufactured at Wemhöner and set up at customer’s site. Multi daylight through feed press lines are arranged one on top of the other or side by side. Feeding and discharging is fully automatic. The precise work piece transport within the press daylight is ensured using linear regulated foil belts. Cylinders arranged above the pressure plates provide a uniform pressure distribution of up to 200 N/cm².

- Ultra-flexible system concepts. Our customers’ needs are extremely diverse. Just like the system concepts of our door and lightweight panel lines. Nevertheless, all Wemhöner systems have three characteristics in common: Developed in dialogue with our customers. Manufactured in accordance with highest German quality standards. Extreme efficiency in day-to-day production processes. In the field of lightweight panel production we offer various different manufacturing concepts. Design requirements for lightweight panels such as frames and inserts for fasteners are technically executed as highly efficient systems based on BOS, BOF and frameless design. The individual components can be easily integrated into existing production lines, or built as a complete production line. Lightweight panel systems are continuously fed and produce elements in a range of 16-120mm thickness. Wemhöner systems offer the most advanced technology for the production of lightweight components in a through feed process.

- Wemhöner special press lines can be found in almost all branches of industry: In the production of high-tech composite materials, laminates and fibre composites or for the vulcanisation process. For example, we develop and manufacture not only embossing presses, mould presses and vulcanisation lines, but also cold press lines or systems for the production of three-layer panels. The product portfolio is further complemented by systems for the automotive industry, for the production of photovoltaic modules and laboratory presses.

- Embossing presses, cold press, mould presses and vulcanisation lines Cold press systems are used for the lamination of wood based panels such as multiplex, MDF, OSB and particle board. Laminate, aluminium, stainless steel or linoleum, glass and stone may be used as coating materials. The material handling for the infeed and outfeed of the press can be customised: single or double sided, manual or fully automatic. Wemhöner embossing and mould presses as well as vulcanisation lines have many possible uses in the production of composite materials: Manufacture of natural rubber-metal products or custom made aramid, fibreglass and carbon fibre products Specific press pressures up to 1,000 N/cm². Depending on the size of the pressing surface this can result in a total force up to 110 000 kN. Temperature settings are in the range of 140 - 180 °C.

- Three-layer panel production Our systems for the manufacture of laminated board include a fully automated laying area in front of the press and a finishing process with a stacking area behind the press. The specific press pressure is up to 100 N/cm², for lateral pressure up to 50 N/cm²

- Laboratory presses Wemhöner laboratory presses are a useful addition in short-cycle pressing and 3D VARIOPRESS® field. Different applications can be inexpensively tested and evaluated. The standard press size is 600 x 600 mm. Special sizes are possible. Press pressures are up to 1,000 N/cm². Temperature settings to 220 °C. Thermal oil or electrical heating panels with optional rear cooling provide heating. Feeding the laboratory press is mainly semi-automatic in order to ensure the shortest possible time spent unpressurised.

- Wemhöner MasterLine® - MasterPrinter®

High-quality solutions for surfaces.

Our vision of surface finishing technologies: thinking beyond the surface. We think in terms of system solutions. The finest example of this is our Wemhöner MasterLine® product group. It stands for high-quality and cost-effective lines for surface finishing of MDF and chipboard panels or other flat materials. The modular concept of the lacquering, direct printing and digital printing systems enables optimum integration in existing lacquering and production lines.

Our vision of finishing in the third dimension.

Wemhöner 3D Variopress® lines: conceived in dialogue with our customers. Manufactured in accordance with highest German quality standards. Installed at our customers’ sites around the world. Day after day, more than 800 Variopress® lines laminate three-dimensional components with thermoplastic foils, veneers and other deformable materials. They enable the production of furniture fronts with glossy surfaces, deeply textured designs and curved fronts. Many of these vacuum press lines incorporate the patented VarioPin®system and our multifunction frame. Wemhöner 3D Variopress®lines stand for the realization of our vision of finishing in the third

- Wemhöner MasterLine® - MasterPrinter®

High-tech for single and multi-coloured patterns using the direct printing method: Wemhöner MasterPrinter® is a highly innovative and powerful printing machine for shaping wood and fantasy decors using the "indirect gravure process". The system is designed to achieve optimum print results for working widths up to 2,600mm. Variable repeat lengths. Single and multi-colour printing in perfection.

- Wemhöner MasterLine® - MasterCoater®

Lacquering, staining, filling: With the MasterCoater® liquid lacquer systems are applied perfectly to wood-based surfaces by rolling. A wide range of fluids can be applied by rolling: including primers, pigments, varnishes, oils, stains,

- Wemhöner MasterLine® - MasterCuring®

UV radiator components for curing of UV radiation-curing lacquering systems: The layout of the modules can be expanded and adapted to match the production technology. The radiation dose is switchable or controllable. Options for infrared reduction variable reflector geometries are available.

- Wemhöner MasterLine® - MasterControl®

Control of process flow over the entire line: Utilizing a decentralised control, the production process is controlled by means of visualisation. This is upgradeable for future plant expansions. PC and PLC technology regulate and control the Wemhöner MasterLine® from feeding to stacking.

Videos

News

Entrepreneur Of The Year 2021 competition

Heiner Wemhöner in the final of the "Entrepreneur Of The Year 2021"